Tennessee Building Codes for Roofing: Everything Homeowners Need to Know

Building codes might sound boring, but they’re actually your best protection when investing in a new roof. These regulations ensure your roof can withstand Tennessee’s weather, protect your family, and maintain your home’s value. Roofing projects in Tennessee must follow state regulations designed to protect homeowners and ensure safe construction practices, as outlined under Tennessee roofing laws.

But here’s the problem: building codes are complex, vary by location, and change regularly. How do you know if your contractor is following the right standards?

At a Knoxville-based roofing company, navigating Tennessee building codes is part of our daily work. This guide breaks down everything you need to know about roofing codes—without the confusing details.

Why Tennessee Roofing Building Codes Matter

Before diving into specific requirements, let’s understand why these codes exist and how they protect you.

Your Safety Comes First

Building codes establish minimum standards for:

- Wind resistance during severe storms

- Fire protection for your family

- Structural integrity under snow and ice loads

- Water infiltration prevention

Tennessee experiences severe weather including high winds, heavy rain, and occasional tornadoes. Codes ensure your roof stands up to these challenges.

Protecting Your Investment

Code compliance affects:

- Home resale value and buyer confidence

- Insurance coverage and claims processing

- Warranty validity from manufacturers

- Legal liability if problems occur

Non-compliant work can cost thousands to correct later and create serious problems when selling your home.

Legal Requirements You Can't Ignore

Tennessee law requires:

- Permits for most roofing projects

- Licensed contractors for work over $25,000

- Inspections at specific project stages

- Certificate of occupancy for some projects

Skipping these requirements creates legal and financial risks that far outweigh any short-term savings.

Understanding the International Residential Code (IRC)

Tennessee adopts the International Residential Code with state-specific modifications. Here’s what that means for your project.

The Foundation: IRC Standards

The IRC provides comprehensive construction standards including:

- Chapter 9: Roof Assemblies covering materials and installation

- Wind load requirements based on geographic zones

- Fire rating standards for different roof types

- Ventilation requirements for attic spaces

Tennessee uses the IRC as its baseline, then adds state-specific amendments addressing local conditions.

Tennessee-Specific Modifications

State amendments address:

- Higher wind zones in certain regions

- Tornado-prone area requirements

- Specific material limitations

- Local climate considerations

Your contractor must know both IRC standards and Tennessee modifications. This expertise distinguishes professional contractors from less qualified operators.

Local Amendments Add Another Layer

Individual counties and cities may add requirements:

- Stricter wind ratings in vulnerable areas

- Enhanced fire protection in wildfire zones

- Historical district restrictions

- Energy efficiency mandates

Always check with your local building department before starting work. What’s acceptable in Nashville might not meet Memphis requirements.

| Code Level | Scope | Example Requirements |

|---|---|---|

| International Residential Code | National baseline | Basic wind resistance, materials |

| Tennessee State Amendments | Statewide additions | Enhanced storm requirements |

| Local County/City Codes | Municipality-specific | Zone-specific wind ratings |

Permit Requirements: When You Need Them

Understanding permit requirements prevents costly delays and legal problems.

Projects Requiring Permits

Most Tennessee jurisdictions require permits for:

Complete Roof Replacements:

- Removing old roofing and installing new systems

- Any project involving structural modifications

- Changes to roof slope or configuration

Major Repairs:

- Replacing more than 25% of roof area

- Structural decking replacement

- Modifications to roof framing

New Construction Additions:

- Room additions requiring new roofing

- Garage or shed construction

- Covered porch additions

Professional contractors like those providing Tennessee roof repair services handle permit applications as part of their service.

Projects Not Requiring Permits

Generally permit-exempt work includes:

- Minor repairs (replacing a few shingles)

- Maintenance work like roof cleaning

- Gutter installation or repair

- Small patch repairs under 100 square feet

However, exemptions vary by jurisdiction. When in doubt, check with your local building department.

The Permit Application Process

Here’s what happens when applying for roofing permits:

Step 1: Submit Application

- Completed permit application form

- Detailed project plans and specifications

- Contractor license information

- Estimated project cost

Step 2: Plan Review

- Building department reviews for code compliance

- May request modifications or additional information

- Reviews typically take 3-10 business days

Step 3: Permit Issuance

- Pay permit fees (usually based on project value)

- Receive permit card to post at work site

- Obtain approved plans

Step 4: Schedule Inspections

- Notify building department before starting work

- Schedule required inspections at proper stages

- Pass all inspections before project completion

Wind Load Requirements: Built for Tennessee Weather

Tennessee’s weather demands specific wind resistance standards.

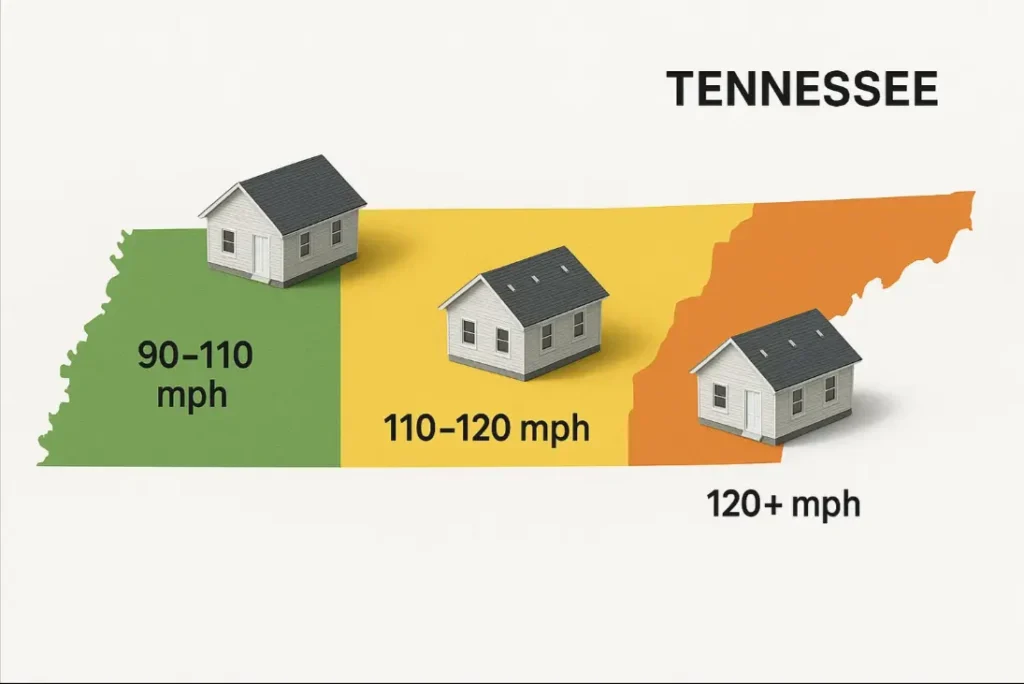

Understanding Wind Zones

Tennessee divides into wind zones based on risk:

Zone 1 (Lower Risk):

- Central Tennessee valleys

- 90-110 mph wind requirements

- Standard installation methods

Zone 2 (Moderate Risk):

- Western and eastern Tennessee

- 110-120 mph wind requirements

- Enhanced fastening patterns

Zone 3 (Higher Risk):

- Exposed hilltops and ridges

- 120+ mph wind requirements

- Specialized installation techniques

Check your property’s specific wind zone through your local building department. This determines the requirements for your residential roof repair or replacement.

Meeting Wind Requirements

Wind resistance comes from several factors:

Proper Fastening:

- Correct nail length and type

- Proper nail placement and quantity

- Adequate penetration into decking

Underlayment:

- Self-adhering membranes in vulnerable areas

- Proper overlap and sealing

- Wind-rated products

Edge Protection:

- Starter strip installation

- Drip edge requirements

- Enhanced fastening at edges and ridges

Material Selection:

- Wind-rated shingles or materials

- Manufacturer installation specifications

- Appropriate for local wind zone

Professional installation following these standards protects your home during severe weather events that Tennessee experiences regularly.

Roof Decking and Structural Requirements

The foundation of any quality roof starts with proper decking and structural support.

Decking Material Standards

Tennessee codes specify:

Minimum Thickness Requirements:

- 7/16″ OSB or plywood for 16″ rafter spacing

- 15/32″ OSB or plywood for 24″ rafter spacing

- Thicker requirements for certain climates

Material Quality:

- Proper grade ratings (typically CDX plywood or better)

- Moisture-resistant materials

- Proper fastening to rafters

Spacing and Support:

- Maximum spans based on material thickness

- Proper support at edges

- Stagger joints for strength

Quality contractors inspect and replace damaged decking before installing new roofing materials. This prevents future problems and ensures code compliance.

Structural Load Requirements

Your roof structure must support:

Dead Loads:

- Roofing material weight

- Decking and framing weight

- Equipment mounted on roof

Live Loads:

- Snow accumulation

- Maintenance worker access

- Temporary construction loads

Wind Uplift Loads:

- Negative pressure during high winds

- Suction forces at edges and corners

- Overall structural wind resistance

Structural modifications require engineering calculations and enhanced inspections. Projects involving solar panel installation often need structural verification.

Ventilation Standards: Critical for Roof Longevity

Proper attic ventilation isn’t optional—it’s required by code and essential for roof performance.

Why Ventilation Requirements Exist

Adequate ventilation prevents:

- Moisture accumulation causing rot and mold

- Ice dam formation in winter

- Excessive heat buildup shortening shingle life

- Structural damage from condensation

Tennessee’s humid climate makes ventilation especially critical.

Minimum Ventilation Requirements

Tennessee codes typically require:

Net Free Ventilation Area:

- 1 square foot per 150 square feet of attic space

- Can reduce to 1:300 with proper vapor barriers

- Balanced between intake and exhaust

Intake Ventilation:

- Soffit vents along roof edges

- Adequate for air to enter freely

- Protected from weather infiltration

Exhaust Ventilation:

- Ridge vents, roof vents, or gable vents

- Located near roof peak for heat escape

- Sized to balance intake volume

Common Ventilation Mistakes

Avoid these code violations:

- Blocking soffit vents with insulation

- Insufficient ventilation area for attic size

- Imbalanced intake/exhaust creating negative pressure

- Mixing ventilation types that fight each other

Professional contractors performing thorough roof inspections evaluate ventilation adequacy and recommend improvements.

Fire Rating Requirements

Fire safety codes protect your family and meet insurance requirements.

Understanding Fire Ratings

Roofing materials receive fire ratings:

Class A (Highest Protection):

- Asphalt shingles with fiberglass base

- Most metal roofing products

- Clay and concrete tiles

- Required in many Tennessee jurisdictions

Class B (Moderate Protection):

- Some wood shingles with treatment

- Certain composite materials

- Limited use in many areas

Class C (Basic Protection):

- Untreated wood shingles

- Some older materials

- Often prohibited in urban areas

Check your local requirements before selecting materials. Most areas require Class A for new installations.

Special Fire Considerations

Additional requirements may apply:

- Wildfire-prone areas need enhanced protection

- Urban interface zones have stricter standards

- Historical districts may have special allowances

- Commercial properties face additional requirements

Insurance companies often require Class A materials regardless of code minimums. Verify requirements before planning your metal roofing project.

Flashing and Water Protection Standards

Proper flashing prevents the most common source of roof leaks.

Critical Flashing Locations

Codes require proper flashing at:

Roof Penetrations:

- Chimneys require counter-flashing

- Plumbing vents need proper boots

- HVAC units require curb flashing

- Skylights need pan flashing systems

Roof Transitions:

- Valley flashing (open or closed)

- Wall/roof intersections

- Dormer connections

- Eave and rake edges

Vulnerable Areas:

- Ice and water shield at eaves

- Step flashing along walls

- Kick-out flashing at wall ends

- Headwall flashing above windows

Professional installation of flashing prevents leaks and ensures code compliance. Many emergency roof repairs result from improperly installed flashing.

Ice and Water Shield Requirements

Tennessee codes require self-adhering waterproof membranes:

Minimum Coverage:

- Extends from eave edge up at least 24″ inside exterior wall

- Enhanced coverage in colder regions

- Additional coverage in valleys

Application Standards:

- Proper surface preparation

- Correct overlap specifications

- Temperature limitations during installation

- Compatibility with roofing material

This protection proves especially important during Tennessee’s occasional ice storms and heavy snow events.

Material-Specific Code Requirements

Different roofing materials have unique code requirements.

Asphalt Shingle Requirements

Most common in Tennessee, asphalt shingles must meet:

Material Standards:

- Minimum weight ratings

- Wind resistance ratings

- Fire classification

- Manufacturer specifications

Installation Requirements:

- Proper fastener type and quantity

- Correct exposure and overlap

- Starter strip requirements

- Hip and ridge specifications

Metal Roofing Codes

Metal roofing systems have specific requirements:

Panel Standards:

- Minimum gauge specifications

- Proper slope requirements (typically 3:12 minimum)

- Fastening methods and spacing

- Thermal expansion allowances

Underlayment:

- Required underlayment type

- Proper installation methods

- Moisture barrier requirements

Flashing and Trim:

- Proper edge treatments

- Penetration flashing details

- Valley construction methods

Tile and Specialty Material Codes

Premium materials like tile require:

- Enhanced structural support for additional weight

- Proper batten installation for attachment

- Specialized underlayment requirements

- Wind-rated attachment systems

These projects often need engineering oversight and enhanced inspections.

| Material Type | Minimum Slope | Wind Rating | Fire Rating | Special Requirements |

|---|---|---|---|---|

| Asphalt Shingles | 2:12 | 110+ mph | Class A | Standard fastening |

| Metal Roofing | 3:12 | 120+ mph | Class A | Thermal expansion |

| Tile | 4:12 | Varies | Class A | Structural support |

| Flat/Low-Slope | 1/4:12 | 90+ mph | Class A | Special membranes |

The Inspection Process: What to Expect

Understanding inspections helps you prepare and avoid delays.

Pre-Construction Inspection

Before work begins:

- Permit verification at the site

- Material staging review

- Site safety assessment

- Property protection measures

Have your contractor post the permit card visibly and ensure all materials meet approved specifications.

Rough Inspection

Conducted after tear-off and decking work:

Inspector Examines:

- Decking condition and attachment

- Structural modifications if any

- Proper fastening to rafters

- Replacement decking quality

Common Issues Found:

- Insufficient decking thickness

- Improper fastening

- Damaged rafters not replaced

- Missing required structural members

Address any deficiencies immediately before proceeding.

Progress Inspection

During installation, inspectors verify:

- Proper underlayment installation

- Flashing details at penetrations

- Valley construction methods

- Ice and water shield placement

Some jurisdictions require multiple progress inspections for complex projects.

Final Inspection

The last inspection before project approval:

Inspector Checks:

Overall installation quality

Code compliance throughout

Proper ventilation installation

Complete flashing details

Site cleanup completion

Required Documentation:

Manufacturer warranties

Material specifications

Disposal receipts

Contractor certification

Pass this inspection to receive your certificate of completion. Many Tennessee building codes are tied directly to who is allowed to perform roofing work. In many cases, homeowners are required to hire qualified professionals who understand and follow these regulations. This is why it’s important to know whether a roofing license is required in Tennessee before hiring a contractor or starting a roofing project.

Common Code Violations and How to Avoid Them

Learn from others’ mistakes to keep your project compliant.

Inadequate Fastening

The Problem:

- Too few nails per shingle

- Wrong nail length or type

- Improper nail placement

- Poor nail penetration

The Solution:

- Follow manufacturer specifications exactly

- Use proper pneumatic pressure settings

- Inspect fastening regularly during installation

- Hire experienced contractors who know requirements

Improper Flashing

The Problem:

- Missing step flashing at walls

- Inadequate valley flashing

- Poor penetration details

- No kick-out flashing

The Solution:

- Use proper flashing materials

- Follow code-compliant details

- Install before roofing material

- Ensure water sheds away from vulnerable areas

Ventilation Deficiencies

The Problem:

- Insufficient ventilation area

- Blocked soffit vents

- Imbalanced intake/exhaust

- Improper vent placement

The Solution:

- Calculate required ventilation accurately

- Keep insulation away from vents

- Balance intake and exhaust equally

- Position exhaust vents properly

Material Non-Compliance

The Problem:

- Using materials not approved for slope

- Wrong fire rating for area

- Insufficient wind resistance

- Improper material storage

The Solution:

- Select appropriate materials during planning

- Verify code compliance before purchasing

- Store materials properly on site

- Use materials within their rated capabilities

Energy Code Requirements

Recent code updates emphasize energy efficiency.

Insulation Standards

Tennessee energy codes require minimum insulation:

Attic Spaces:

- R-38 minimum in most Tennessee zones

- R-49 in colder regions

- Proper installation without compression

- Maintained ventilation clearances

Cathedral Ceilings:

- R-30 minimum with proper ventilation

- Alternative: spray foam systems

- Continuous insulation barriers

- Vapor retarder requirements

Radiant Barrier Options

While not always required, radiant barriers improve efficiency:

- Installed on bottom of roof decking

- Reduces summer heat gain

- Lowers cooling costs

- May qualify for energy credits

Cool Roof Requirements

Some jurisdictions incentivize or require:

- High solar reflectance materials

- Thermal emittance standards

- Cool color options for metal roofs

- Energy Star ratings

These requirements particularly apply to commercial roofing projects.

Working with Building Departments

Positive relationships with building officials streamline projects.

Before You Apply

Prepare by:

- Researching requirements thoroughly

- Gathering all documentation before applying

- Understanding local amendments

- Asking questions before submitting

Most building departments offer pre-application consultations. Use this service for complex projects.

During the Project

Maintain compliance by:

- Scheduling inspections in advance

- Being present during inspections when possible

- Addressing deficiencies immediately

- Maintaining communication with inspectors

Common Building Department Questions

Be prepared to answer:

- What materials are you using? Have specifications ready

- Who’s doing the work? Provide contractor license information

- When will you need inspections? Give realistic timelines

- Are there any structural changes? Have engineering documents if needed

Transparency and preparedness create positive working relationships.

Special Situations and Exceptions

Some projects face unique code challenges.

Historical Properties

Homes in historical districts may need:

- Historical commission approval

- Material restrictions matching original construction

- Specialized installation methods

- Documentation of historical accuracy

Work with contractors experienced in historical renovation.

HOA-Restricted Communities

Homeowners associations often add requirements:

- Specific color restrictions

- Material type limitations

- Architectural review board approval

- Enhanced aesthetic standards

Check HOA rules before selecting materials—they may be stricter than building codes.

Unusual Roof Designs

Complex designs need special attention:

- Flat or low-slope roofs under 2:12

- Curved or barrel roofs

- Green roof systems

- Integrated solar systems

These projects typically require engineering oversight and enhanced inspections.

Consequences of Non-Compliance

Understanding risks motivates proper code compliance.

Immediate Consequences

Non-compliant work creates:

- Failed inspections delaying project completion

- Stop work orders halting construction

- Correction costs for compliance fixes

- Extended project timelines

Long-Term Problems

Code violations cause:

- Insurance claim denials

- Manufacturer warranty voids

- Resale difficulties when selling

- Legal liability for injuries or damage

Financial Impact

Non-compliance costs include:

- Tear-off and replacement of non-compliant work

- Additional permit fees

- Extended contractor costs

- Potential fines from building departments

Proper compliance from the start saves money and headaches.

Choosing Code-Compliant Contractors

The right contractor makes code compliance easy.

What to Look For

Qualified contractors demonstrate:

Code Knowledge:

- Understanding of IRC and Tennessee amendments

- Familiarity with local requirements

- Current with code updates

- Proper interpretation of standards

Permit Experience:

- Regular permit applications

- Good relationships with building departments

- Clean inspection records

- Proper documentation practices

Installation Expertise:

- Follows manufacturer specifications

- Uses proper techniques and materials

- Maintains quality control

- Addresses issues proactively

At Daniel Hood Roofing, we pride ourselves on code-compliant installations that pass inspections the first time.

Questions to Ask Contractors

Verify code competency by asking:

“How familiar are you with Tennessee roofing codes?”

- Detailed answers show knowledge

- Vague responses raise concerns

“Have you worked in my jurisdiction before?”

- Local experience means smoother permitting

- New-to-area contractors may face learning curves

“What’s your inspection pass rate?”

- High pass rates indicate quality work

- Multiple failures suggest problems

“Who handles permit applications and inspections?”

- Contractors should manage this process

- Homeowner responsibility signals inexperience

Red Flags to Avoid

Watch for warning signs:

- Suggesting you skip permits

- Claiming codes don’t apply

- No experience with local building department

- Can’t explain code requirements

- History of failed inspections

These signs indicate contractors who cut corners and create future problems.

Resources for Code Information

Access these resources for specific code questions:

Official Sources

International Code Council (ICC):

- Publishes the IRC

- Offers code books and resources

- Provides training and certification

Tennessee Department of Commerce & Insurance:

- State code adoptions and amendments

- Licensing board information

- Consumer protection resources

Local Building Departments:

- Municipality-specific requirements

- Permit applications and fees

- Inspection scheduling

- Local amendments and interpretations

Professional Organizations

Industry groups provide guidance:

Tennessee Roofing Contractors Association

National Roofing Contractors Association

Manufacturer technical support

Professional contractor associations

Beyond state and local codes, many professional roofers also follow industry standards set by trusted organizations. Groups such as the Tennessee Roofing Contractors Association help promote ethical practices, proper installation methods, and ongoing education to ensure roofing work meets both safety and quality expectations.

Online Resources

Helpful websites include:

- Building department websites

- Code reference sites

- Manufacturer installation guides

- Professional association resources

Your Action Plan for Code-Compliant Roofing

Ready to start your roofing project? Follow these steps:

Step 1: Research Your Local Requirements

- Contact your building department

- Understand permit requirements

- Identify specific local amendments

- Note any special restrictions (HOA, historical, etc.)

Step 2: Select Qualified Contractors

- Interview multiple contractors

- Verify code knowledge

- Check inspection history

- Review past projects

Step 3: Plan for Compliance

- Choose code-approved materials

- Understand inspection schedule

- Budget for permit fees

- Allow time for reviews and inspections

Step 4: Monitor the Process

- Verify permit posting

- Attend inspections when possible

- Address deficiencies promptly

- Maintain documentation

Step 5: Complete Final Requirements

- Pass final inspection

- Obtain completion certificate

- File warranty documents

- Keep all records for future reference

Whether you need emergency repairs, routine maintenance, or complete replacement, code-compliant work protects your investment and your family.

Share your project details to receive code-compliant roofing solutions delivered with proven expertise and transparent service.