Metal Roofing Repair Secrets That Could Save You Thousands in Damage

Last month, I got a call from a homeowner who’d spent $800 trying to fix a “simple” metal roof leak. Three different attempts, three failures, and water still dripping into his living room every time it rained. Sound familiar?

The roofing industry has exploded recently – according to IBISWorld, the roofing contractors industry in the U.S. will reach $76.4 billion in revenue in 2025, reflecting a 0.8% increase from the previous year due to increasingly frequent extreme weather events requiring roofing repair and replacement services. This growth means understanding proper metal roofing repair has become more critical than ever.

Here’s what most people miss about metal roof repairs: it’s not about slapping sealant on a leak and calling it good. Different materials need different approaches, water travels in mysterious ways, and the wrong “quick fix” can actually make things worse.

Let me walk you through what really works when fixing metal roofs – from finding the actual source of problems to repairs that last decades instead of months.

Table of Contents

Understanding Your Metal Roof Before Problems Strike

Finding and Fixing Metal Roof Leaks the Right Way

Professional Repair Techniques That Actually Work

Maintenance Programs That Prevent Expensive Surprises

Quality Control and Warranty Protection

TL;DR

Different metal roofing materials (steel, aluminum, copper) require specific repair approaches and compatible materials to prevent galvanic corrosion

Most metal roof leaks originate from fastener points, seams, and flashing rather than the metal panels themselves

Emergency repairs need immediate temporary solutions while permanent fixes require proper weather conditions and surface preparation

Professional repairs involve systematic diagnosis, structural assessment, and specialized techniques for seams and joints

Regular bi-annual inspections and preventive maintenance significantly reduce major repair costs

Proper documentation and testing ensure repairs meet warranty requirements and long-term performance standards

Understanding Your Metal Roof Before Problems Strike

Look, I get it – when water’s dripping into your house, the last thing you want is a materials science lesson. But here’s the thing: slapping the wrong sealant on aluminum can actually make your leak worse. Trust me, I’ve seen it happen.

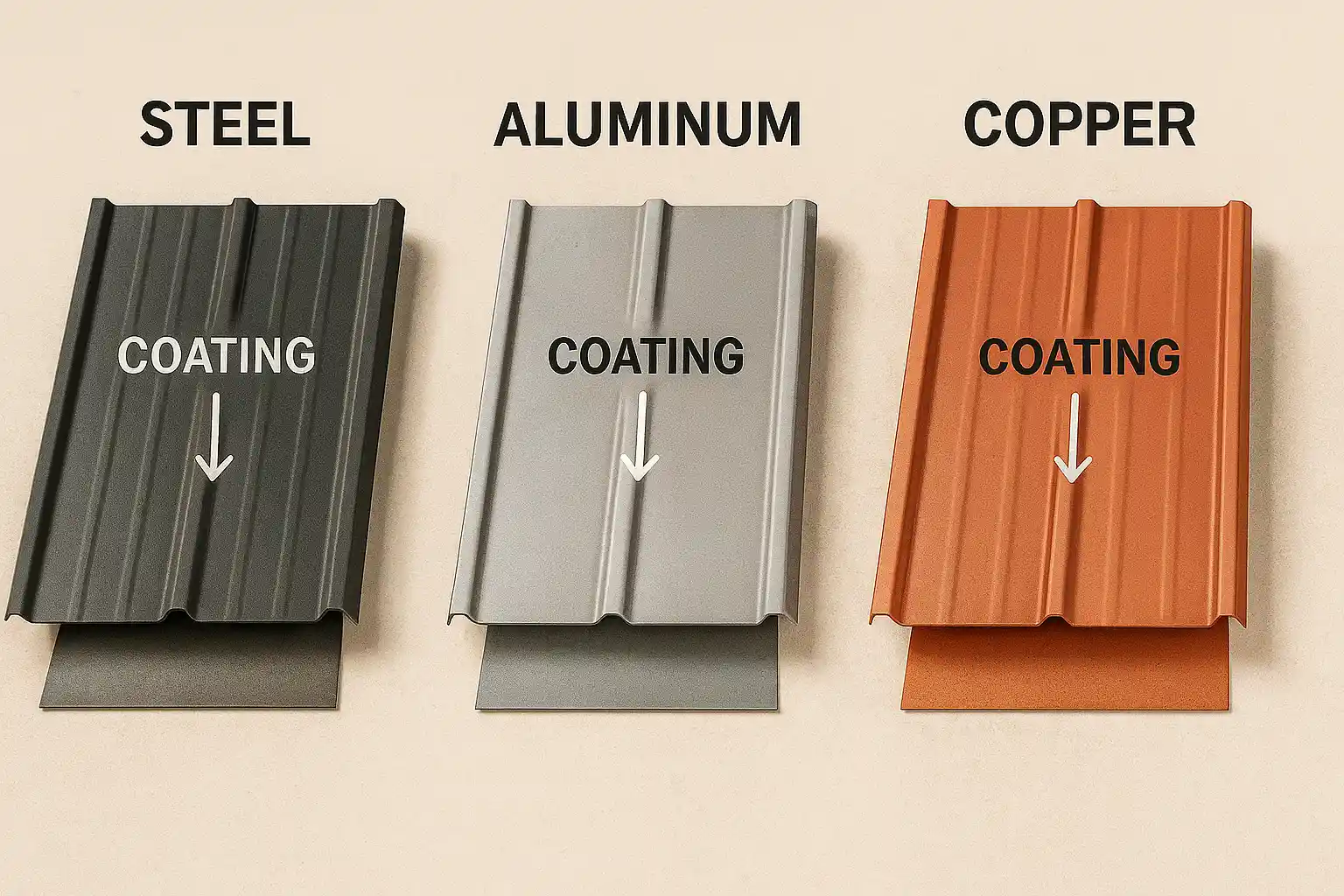

Think of it this way – you wouldn’t put diesel in a gas car, right? Same principle applies to metal roofs. Steel, aluminum, and copper all have their quirks, and mixing the wrong materials creates problems that’ll cost you way more than the original leak.

Before diving into specific repair techniques, understanding the various components that make up your roofing system helps identify potential failure points and repair priorities.

Why Material Matters More Than You Think

Steel roofs are tough but they fight rust constantly. Aluminum is lightweight but soft as butter – handle it wrong and you’ll dent it just looking at it funny. Copper? Beautiful stuff, but it throws a tantrum if you use the wrong fasteners with it.

Each material needs different treatment, like different dog breeds need different care. You can’t train a German Shepherd the same way you’d train a Golden Retriever.

Here’s what really happens when you get this wrong: I worked on a steel roof in Ohio where the homeowner kept patching leaks with generic hardware store sealant. Every “fix” lasted maybe three months before failing again. Turns out, rust was spreading underneath each patch because he skipped the primer step. Once we properly cleaned the area, applied rust-inhibiting primer, and used steel-compatible sealant, that repair held strong for over two years through brutal winters and scorching summers.

Last month, I got a call from a homeowner who’d spent $800 trying to fix a “simple” metal roof leak. Three different attempts, three failures, and water still dripping into his living room every time it rained. Sound familiar?

The roofing industry has exploded recently – according to IBISWorld, the roofing contractors industry in the U.S. will reach $76.4 billion in revenue in 2025, reflecting a 0.8% increase from the previous year due to increasingly frequent extreme weather events requiring roofing repair and replacement services. This growth means understanding proper metal roofing repair has become more critical than ever.

Here’s what most people miss about metal roof repairs: it’s not about slapping sealant on a leak and calling it good. Different materials need different approaches, water travels in mysterious ways, and the wrong “quick fix” can actually make things worse.

Let me walk you through what really works when fixing metal roofs – from finding the actual source of problems to repairs that last decades instead of months.

Steel Roofing: The Workhorse With Trust Issues

Steel roofs are probably what you’ll encounter most often, and they’re constantly battling oxidation. When I’m repairing steel, surface preparation becomes absolutely critical because any rust left behind will keep spreading under your repair like a cancer.

You need specialized rust-inhibiting primers and compatible topcoats that can flex with thermal movement. Skip these steps, and you’re just wasting time and money on repairs that’ll fail within months.

Aluminum and Copper: The High-Maintenance Cousins

These premium materials are like expensive sports cars – they perform great when treated right, but they’re unforgiving if you mess up. Aluminum is soft and prone to damage from ham-fisted repairs. Copper develops that gorgeous patina over time, but mix it with the wrong metals and you’ll get galvanic corrosion that can eat through your roof faster than you’d believe.

With copper, I use only stainless steel or copper fasteners – never mix metals. The sealants need to be compatible too, or you’ll create problems worse than what you started with.

Reading Your Roof's Warning Signs

Your roof talks to you – you just need to know its language. That loose screw isn’t just annoying; it’s telling you about thermal stress. Those tiny cracks in the sealant? They’re saying “fix me now or deal with a bigger problem later.”

Most homeowners point to obvious damage while missing the real problems lurking nearby. Metal roof issues rarely announce themselves with dramatic failures – they start small and grow like weeds.

Regular inspections can help identify early warning signs, and knowing key indicators that your roof needs attention prevents minor issues from becoming major headaches.

Thermal Movement: The Silent Troublemaker

Metal roofs expand and contract constantly like they’re breathing, and this movement creates predictable stress points that eventually give up. Look for elongated fastener holes, cracked sealant lines, and separation at joints – these are your roof’s way of saying “I’m stressed out.”

Understanding your local climate helps predict where these problems develop. Areas with wild temperature swings see more thermal movement damage, while coastal regions deal more with corrosion issues from salt air.

Weather Damage Patterns You Can't Ignore

Different weather creates distinct damage signatures. Hail damage is usually obvious – you’ll see dents. But wind damage can be sneaky – lifted edges, loose fasteners, or damaged flashing that won’t leak immediately but will fail during the next big storm.

Understanding how winter weather affects metal roofing systems helps predict and prevent seasonal damage patterns.

Fastener Failure: The Weak Link

Fasteners are like the weak link in a chain – when they fail, everything else follows. Loose fasteners show up as slight gaps or movement around the fastener head. Sealant failure starts with small cracks that might look harmless, but water will find those tiny openings like a bloodhound.

Check fastener tightness systematically and look for sealant that’s become hard, cracked, or pulled away from surfaces. Catch these early, and you’re looking at a $20 fix instead of a $2,000 problem.

Finding and Fixing Metal Roof Leaks the Right Way

Here’s what drives me crazy: people see water damage on their ceiling and immediately climb up to patch the spot directly above it. That’s like seeing smoke and assuming the fire is right underneath – water travels, folks.

Effective leak repair starts with playing detective, not playing whack-a-mole with sealant. You need to find where water is actually entering and why it’s entering there, not just where it’s showing up inside your house.

Playing Detective With Water Damage

Every leak investigation starts inside your house, not on the roof. I follow water stains like breadcrumbs, tracing them back through the attic to where they actually started. Sometimes that wet spot in your living room is coming from a failed flashing connection 20 feet away.

This detective work takes time, but it ensures you’re fixing the actual problem rather than treating symptoms. Water rarely enters where you see damage – it’s sneaky like that.

When dealing with active leaks, knowing proper emergency response steps can minimize interior damage while you prepare for permanent repairs.

Following the Water Trail

Starting from interior damage and working backward might seem strange, but it’s the most efficient approach. Water stains, mineral deposits, and damage patterns tell a story about where water entered and how it traveled through your roof system.

Recently worked a case in Michigan where the homeowner was convinced his leak was directly above the dining room. Interior investigation showed water traveling along a roof beam from way up in the northeast corner – a loose flashing connection nowhere near where he thought the problem was. Following the evidence saved us hours of random roof searching.

Common Leak Sources (It's Not What You Think)

Most people assume metal roof leaks come from holes in the panels. Wrong. The metal panels are usually fine – it’s the connections, penetrations, and transitions where problems develop.

Real Leak Sources:

Fastener points (loose screws, failed gaskets)

Seam connections and joints

Flashing around chimneys, vents, skylights

Transitions between roof sections

Emergency Fixes That Actually Help

When water’s pouring in during a storm, you need to stop it fast. But here’s the key – don’t try to do permanent repairs in bad weather. You’ll just create more problems.

Emergency repairs should buy you time for proper repairs when conditions improve. Think of it as first aid for your roof – stop the bleeding so you can get to the hospital for real treatment.

The Emergency Repair Reality Check

Some sealants won’t cure in cold temperatures. Others can’t be applied in high humidity or wet conditions. Fighting these limitations usually results in failed repairs and wasted materials.

Work with weather conditions rather than against them. Sometimes that means containing interior damage and waiting for better conditions to access the roof safely.

Emergency Repair Kit Essentials:

Butyl tape for immediate sealing

EternaBond repair tape for temporary patches

Tarps and tie-downs for large area coverage

Stainless steel fasteners (various sizes)

Roofing cement for wet condition sealing

Safety equipment (non-negotiable)

Safety During Storms (Don't Be a Hero)

Emergency situations create pressure to take shortcuts with safety, but that’s exactly when accidents happen. Wet metal roofs are incredibly slippery, and emergency conditions often mean poor visibility and unstable weather.

Never compromise on safety equipment or protocols, even during urgent repairs. Sometimes the safest approach is to contain interior damage and wait for conditions that allow safe roof access.

Understanding proper safety protocols for roof work becomes even more critical during emergency situations.

permanent Solutios That Actually Last

Real permanent repairs require patience, proper materials, and techniques that address the root cause rather than symptoms. The difference between a repair that lasts two months and one that lasts twenty years often comes down to surface preparation and material compatibility.

True permanent repairs start with understanding why the leak developed in the first place. Was it material failure, installation error, or normal wear? Your repair method needs to address that underlying cause.

Surface Preparation: The Boring Step That Matters Most

Proper surface preparation is about as exciting as watching paint dry, but it’s what separates professional repairs from DIY disasters. Any contamination, moisture, or loose material will cause adhesion failure – guaranteed.

Clean surfaces thoroughly, remove all rust and loose material, and ensure everything is completely dry before applying repair materials. Skip this step, and you’re just wasting time and money.

Material Selection That Makes Sense

Materials isn’t just about reading labels – it’s about understanding how different materials behave together over time. Some combinations work fine initially but fail after thermal cycling or UV exposure.

Match repair materials to existing roof materials and consider local environmental conditions. A sealant that works great in Arizona might fail miserably in Minnesota.

Over the past three years, nearly 31% of homeowners nationwide have pursued roof renovation, repair, or maintenance projects, with most hiring roofing contractors but over 14% attempting DIY repairs that often require professional correction later.

Professional Repair Techniques That Actually Work

Some repairs look simple but aren’t. Standing seam repairs need special tools and knowledge. Structural issues require engineering assessment. Coating applications can go spectacularly wrong if you skip surface preparation steps. Complex metal roofing repairs go beyond basic maintenance and require specialized knowledge that most homeowners simply don’t have access to. When repairs involve underlying structural issues, those must be addressed before surface repairs can be effective.

When DIY Becomes Dangerous Territory

I’m all for homeowners handling basic maintenance, but some repairs require professional equipment and expertise. If you’re dealing with structural damage, complex seam repairs, or widespread coating failure, call someone who does this for a living.

Recently saw a homeowner attempt a standing seam repair with regular household pliers. Damaged three panels trying to fix one small problem. The professional repair ended up costing more than if he’d called initially, plus he had to pay for the additional damage he created.

Structural Issues You Can't Ignore

Some metal roof problems are symptoms of deeper structural issues that no amount of surface repair will fix permanently. Sagging areas, unusual deflection, or cracked decking can indicate structural problems that will stress any repair materials beyond their limits.

Before attempting complex repairs, evaluate whether the roof structure can adequately support the metal roofing system. Sometimes you need to remove sections of metal roofing to access and repair underlying structural problems.

With recent wildfires destroying over 16,000 structures, “Photos from this disaster show metal-roofed homes still standing in the middle of burned debris from the rest of the neighborhood” according to Roofing Contractor, highlighting the importance of proper structural support for these resilient roofing systems.

Seam Repair Complexity

Standing seam repairs require different tools and techniques than exposed fastener systems. Some joints need welding or soldering for permanent repairs. Get this wrong, and you’ll compromise the entire roof section.

Coating Applications: Easier Said Than Done

Protective coatings can address widespread surface deterioration and extend metal roof life significantly when applied correctly. However, coating application is more complex than it appears – surface preparation is critical, and application techniques affect both appearance and performance.

Poor coating jobs fail spectacularly because someone skipped preparation steps or used incompatible materials. The surface must be completely clean and dry before coating application, and environmental conditions during preparation affect the success of subsequent coating work.

Surface Preparation for Coatings

Proper surface preparation for coatings includes cleaning, degreasing, rust removal, and sometimes complete removal of existing coatings depending on conditions. Mechanical cleaning methods, chemical treatments, and pressure washing must be matched to specific situations.

The surface must be completely clean and dry before coating application. Environmental conditions during preparation – temperature, humidity, wind – all affect whether the coating will adhere properly and cure correctly.

Coating System Selection

Choosing the right coating system requires understanding existing roof conditions, environmental exposure, and expected service life requirements. Some coatings work well over existing treatments, others require complete removal of previous coatings.

Consider factors like thermal cycling, UV exposure, chemical exposure, and maintenance requirements when selecting coating systems. The goal is matching coating capabilities to actual service conditions your roof will experience.

Maintenance Programs That Prevent Expensive Surprises

The best repair is the one you never have to make. Proactive maintenance has saved my clients thousands of dollars in major repair costs while extending metal roof service life well beyond typical expectations.

Regular professional inspections catch problems before they become costly repairs. The key is consistency – sporadic maintenance efforts don’t provide the same protection as regular, systematic programs.

Understanding common types of roofing damage helps prioritize maintenance efforts and catch problems early.

Inspection Programs That Actually Work

Regular professional inspections form the backbone of effective metal roof maintenance, but timing and focus make all the difference. Different seasons reveal different types of damage, so inspection protocols need to match seasonal patterns.

Spring inspections focus on winter damage and summer preparation. Fall inspections assess summer damage and prepare for winter weather. Post-storm assessments catch hidden damage that might not be immediately apparent.

Seasonal Inspection Strategy

Spring and fall inspections serve different purposes because they’re looking for different problems. Spring inspections reveal winter damage – ice effects, thermal cycling stress, and moisture infiltration that developed during cold months.

Fall inspections prepare for winter while assessing summer damage from UV exposure, thermal stress, and storm activity. Using different checklists for each season ensures you’re focusing on the right potential problems.

Spring Focus Areas:

Ice dam damage and water infiltration

Thermal movement effects on fasteners

Sealant condition after freeze-thaw cycles

Winter storm damage assessment

Drainage system cleaning and preparation

Fall Preparation Tasks:

Summer UV damage to coatings and sealants

Thermal expansion effects on seams

Storm damage from summer weather

Winter preparation for drainage systems

Fastener tightness after thermal cycling

Post-Storm Assessment

Storm damage isn’t always immediately obvious on metal roofs. Systematic post-storm inspections often reveal problems that won’t show up as leaks until the next major weather event.

Wind damage can lift edges or loosen fasteners without creating immediate leaks. Hail damage might compromise coatings or create stress points that fail later. Document all findings with photos because insurance claims often require this documentation.

Preventive Maintenance That Pays Off

Regular maintenance tasks prevent minor issues from developing into major repair needs while maintaining optimal roof performance. Fastener maintenance and sealant renewal programs provide the biggest return on investment because these are the most common failure points.

Perform these tasks based on condition and age rather than waiting for obvious problems to develop. Prevention costs far less than emergency repairs.

Fastener Maintenance Programs

Regular fastener inspection and preventive replacement prevents the most common source of metal roof leaks. Check fastener tightness systematically, looking for loose fasteners, damaged gaskets, or signs of corrosion.

Preventive replacement of fasteners showing early deterioration signs costs far less than emergency leak repairs. Maintain detailed records of fastener replacement to track patterns and predict future maintenance needs.

Sealant Renewal Strategy

Proactive sealant replacement based on age and condition prevents water intrusion at vulnerable points before leaks develop. Different sealant types have different service lives, and environmental conditions affect deterioration rates.

Inspect sealant condition during regular maintenance visits and replace sealants showing signs of hardening, cracking, or separation before they fail completely. This preventive approach eliminates most emergency leak situations.

A study conducted by the Metal Construction Agency found that sealant was the deciding factor in service life of metal roofs, with butyl sealants showing no deterioration in tensile strength and estimating service life could last over 60 years.

Quality Control and Warranty Protection

Good repairs aren’t just about stopping leaks – they’re about maintaining your roof’s warranty and ensuring long-term performance. Proper testing methods verify repair effectiveness and identify remaining vulnerabilities before considering work complete.

Documentation requirements protect warranty coverage and provide valuable information for future maintenance and repairs. Quality control proves that good work was done and ensures it continues performing as expected.

Testing Your Repairs

Never consider a repair complete until you’ve tested it. Controlled water testing shows whether the fix actually works under realistic conditions, and understanding how temperature changes affect repairs helps predict long-term performance.

Testing isn’t just about immediate leak prevention – it’s about ensuring repairs will perform under the full range of conditions they’ll encounter during their service life.

Water Testing That Makes Sense

Controlled water testing using hoses and spray equipment simulates rain conditions to verify leak repairs work under realistic conditions. Test repairs systematically, starting with light spray and gradually increasing intensity to match severe weather conditions.

Testing often reveals secondary problems or incomplete repairs that aren’t obvious during dry conditions. Document all testing procedures and results for warranty purposes and future reference.

Temperature Considerations

Understanding how temperature changes affect repairs helps predict long-term performance and identify potential failure points. Metal roofs expand and contract significantly with temperature changes, and repair materials must accommodate this movement without failing.

Consider local climate conditions and seasonal temperature ranges when evaluating repair performance and predicting service life.

Documentation That Protects You

Proper documentation protects warranty coverage and provides valuable information for future maintenance and repairs. Maintain detailed records of materials used, procedures followed, and conditions encountered during repair work.

This documentation proves essential for warranty claims and helps guide future maintenance decisions.

What to Document

Document materials used, procedures followed, and conditions encountered to maintain warranty coverage and guide future work. Photograph repair areas before, during, and after work completion. Maintain material receipts and specifications, and record environmental conditions during repair work.

This documentation package proves invaluable when warranty issues arise or when planning future maintenance activities.

Warranty Compliance Requirements

Ensure all repairs comply with manufacturer specifications to maintain material warranties and avoid coverage disputes. Stay current with manufacturer requirements and use only approved materials and procedures for warranty-covered repairs.

Non-compliant repairs can void warranties on entire roof sections, making compliance essential for long-term protection and cost control.

When you’re dealing with metal roofing repair challenges that seem overwhelming, Daniel Hood Roofing Systems brings the systematic approach and attention to detail that complex repairs demand. We understand that metal roof problems rarely have simple solutions, and our team has the specialized knowledge and equipment needed for professional-grade repairs that actually last.

Our same-day inspection services can quickly identify the real source of your metal roof problems, whether it’s hidden structural issues, failed seams, or deteriorating fasteners. We provide detailed diagnostic reports that explain what’s wrong, why it happened, and how to prevent similar problems in the future. With transparent pricing and financing options, professional metal roof repairs become accessible when you need them most.

Ready to solve your metal roofing problems permanently? Contact Daniel Hood Roofing Systems today for a comprehensive inspection and repair estimate that addresses the root cause of your issues.

Final Thoughts

Metal roofing repair isn’t something you want to learn through trial and error on your own roof. The techniques and knowledge shared here represent years of experience dealing with every type of metal roof problem imaginable.

The key takeaway? Successful repairs require understanding specific materials you’re working with, using systematic diagnostic approaches, and never cutting corners on surface preparation or material compatibility.

What surprises most people is how much money preventive maintenance saves compared to emergency repairs. Those bi-annual inspections and fastener maintenance programs might seem unnecessary, but they prevent the kind of major problems that cost thousands to fix properly.

Remember that metal roofing systems are engineered solutions, not just sheets of metal thrown over your house. Each component serves a specific purpose, and repairs need to maintain that original design intent to be truly effective. When in doubt, consult with professionals who understand these systems and have the tools and experience to diagnose problems correctly the first time.